In luxury vehicles such as the Mercedes-Benz V-Class V300L, every detail of the interior contributes to the overall perception of quality and sophistication. One often overlooked yet critical component is the OEM floor carpet. Shenzer Automotive, a distinguished leader in premium car interior solutions since 1958, specializes in delivering custom OEM floor carpets that perfectly fit the V300L’s specifications. These carpets fuse precise engineering, high-grade materials, and rigorous quality control to ensure durability, comfort, and luxury.

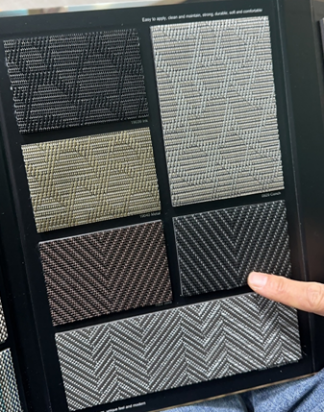

The journey of Shenzer’s floor carpet customization begins with selecting the finest materials, certified to meet or exceed Mercedes-Benz’s high-performance standards. Crafted from high-density fibers, these carpets provide exceptional resistance to wear and tear caused by day-to-day vehicle use—foot traffic, dirt, moisture, and temperature changes.

Shenzer’s carpets undergo a fire-retardant treatment and are manufactured to be odorless, supporting passenger safety and preserving a fresh interior environment. The plush texture engages senses with a velvety soft touch, enhancing passenger comfort on even long journeys. Additionally, an acoustic backing layer integrates into the carpet's design, effectively insulating the cabin against road and engine noise, which helps maintain the serene ambiance synonymous with the Mercedes-Benz brand.

Using advanced Computer-Aided Design (CAD) systems, Shenzer meticulously maps the Mercedes-Benz V300L’s cabin floor space, including its long and extra-long wheelbase variations. This process accounts for every contour, fastening component, seat rail, and vent to build a high-fidelity digital model of the vehicle’s interior floor.

Inspired by this digital model, each carpet is produced using laser cutting technology for unprecedented precision. Pre-cut openings are designed into the carpet for components such as seat brackets and air vents, ensuring effortless compatibility with factory mounting points. This careful design eliminates material gaps or overlaps, allowing quick and secure installation either during the vehicle assembly or aftermarket upgrades.

The manufacturing process integrates state-of-the-art automation with human expertise. Automated machinery handles tufting—the insertion of millions of carpet fibers into a durable backing—robotic cutting, and weld bonding to achieve consistent size and shape. Skilled craftspeople then perform detailed inspections, carefully finishing edges and verifying aesthetic standards to match luxury vehicle expectations.

Materials entering the production line undergo strict raw material testing for fiber strength, dye adherence, and chemical safety. Finished carpets are tested against multiple quality benchmarks, including:

Shenzer places paramount importance on environmental stewardship and passenger health. By sourcing low-VOC (Volatile Organic Compound) materials and employing eco-friendly dyeing and bonding processes, the company actively reduces the ecological impact of its carpets. These materials meet stringent global environmental regulations, assuring a safe in-cabin environment.

High fire resistance is embedded into the carpet fibers, certified by leading automotive and safety authorities, providing peace of mind to passengers and reinforcing regulatory compliance for automakers.

Shenzer’s use of premium materials and advanced manufacturing ensures that floor carpets exhibit outstanding durability, minimizing repair or replacement frequency and associated costs for fleet managers and dealers.

Flexible, precise design facilitates swift fitting, reducing labor time during vehicle assembly or maintenance. Perfect OEM compatibility also mitigates installation errors, cutting costly downtime.

By improving acoustic insulation and offering superior softness, Shenzer carpets contribute significantly to passenger comfort, a critical factor influencing customer satisfaction and loyalty within the luxury automotive market.

Strict adherence to OEM specifications means Shenzer carpets preserve vehicle factory warranties, a vital consideration for manufacturers, dealers, and end customers.

Shenzer pushes boundaries by incorporating aerospace-grade materials, such as carbon fiber composites in carpet construction, to reduce weight without compromising durability. This approach is aligned with ongoing trends in automotive manufacturing focusing on material innovations for performance enhancement.

The company continuously enhances production through digital and automated manufacturing systems, which improve consistency, reduce production lead times, and optimize costs — ensuring Shenzer remains competitive as a premier OEM supplier.

Shenzer Automotive's bespoke OEM floor carpet solutions for the Mercedes-Benz V-Class V300L epitomize the harmonious merger of craftsmanship, technology, and sustainability. Through its commitment to using top-tier materials, precise engineering, rigorous quality controls, and environmental responsibility, Shenzer enhances the luxury vehicle cabin experience.

Automakers and aftermarket partners choosing Shenzer benefit from durable, comfortable, and safety-compliant carpet solutions tailored for exacting Mercedes-Benz standards. Shenzer stands as a reliable, innovative partner committed to elevating vehicle interiors globally.

Copyright © 2024 Shenzer Automobile - Privacy policy